The Significance of an Optical Fibre Diameter Analyser in Preserving Industry Requirements

The importance of an Optical Fibre Diameter Analyser can not be overstated in the context of market standards. This innovation assures precise measurements, which are essential for ideal signal transmission and reduced depletion. By detecting variances early, makers can copyright rigorous quality assurance measures. The ramifications of these measurements expand beyond compliance. Revealing the more comprehensive influence on system performance discloses intricacies that warrant more exploration.

Comprehending Optical Fibre Diameter Evaluation

Optical fibre diameter analysis plays a vital duty in guaranteeing the performance and dependability of fibre optic systems. Accurate measurement of fibre diameter is essential, as it directly influences signal transmission efficiency and total system honesty. Variations in diameter can lead to enhanced depletion, reduced data transfer, and greater vulnerability to environmental elements.

By employing specific dimension strategies, manufacturers can maintain strict quality assurance, making certain that fibers satisfy sector requirements. This analysis additionally assists in the recognition of defects or variances during manufacturing, permitting prompt rehabilitative actions.

Comprehending the diameter specifications help in the choice of proper connectors and installations, therefore enhancing compatibility within the network. Generally, extensive optical fibre diameter evaluation is a fundamental aspect of fibre optic technology, underpinning developments in telecommunications, data transmission, and various applications throughout various sectors.

Trick Features of Optical Fibre Diameter Analysers

Optical fibre diameter analysers are equipped with a number of essential features that improve their capability. Remarkable amongst these are precision measurement capacities, which guarantee precise analyses, and real-time surveillance features that supply immediate responses throughout the analysis process. In addition, a straightforward interface style promotes very easy operation, making these gadgets accessible to a larger variety of individuals.

Accuracy Measurement Capabilities

When it pertains to assuring top quality fibre manufacturing, accuracy measurement capacities are critical in diameter analysers. These tools make use of sophisticated technologies to deliver accurate dimensions of fibre diameter, allowing makers to maintain strict resistances. High-resolution optics and innovative algorithms enable the detection of min variants in diameter, vital for generating reputable and constant optical fibres. Furthermore, the capability to measure across a large range of diameters boosts versatility, suiting numerous production requirements. The integration of calibration criteria makes certain that measurements remain precise over time, minimizing the threat of defects. By utilizing these precision measurement abilities, suppliers can promote market criteria, enhance product top quality, and eventually drive consumer satisfaction in the affordable fibre optics market.

Real-Time Monitoring Attributes

Real-time monitoring functions are vital for enhancing the effectiveness and performance of fibre production procedures. These capabilities make it possible for continual analysis of optical fibre diameter throughout production, ensuring that any variances from specified standards are right away identified. By providing instantaneous responses, manufacturers can without delay change specifications, reducing waste and preserving quality control. Furthermore, real-time monitoring helps with the identification of trends and patterns in production information, using important understandings for process optimization. The integration of these features into optical fibre diameter analysers supports proactive decision-making, equipping operators to respond promptly to prospective problems. Subsequently, the execution of real-time surveillance not just maintains industry standards but also enhances total productivity and item reliability.

User-Friendly Interface Design

A properly designed interface is crucial for the efficient procedure of optical fibre diameter analysers. Such interfaces prioritize simpleness and accessibility, permitting individuals to browse the system with ease. Secret functions typically consist of user-friendly food selections, clear graphical representations of data, and adjustable setups to suit numerous individual preferences. Real-time feedback mechanisms boost the user experience by giving immediate understandings into dimensions. Additionally, efficient error messaging guides individuals in fixing issues swiftly, decreasing downtime. The incorporation of touchscreens and responsive styles better helps with communication, making it less complicated for professionals to operate the analyser in varied environments. Inevitably, an easy to use user interface not only enhances effectiveness yet likewise boosts the overall precision of the dimensions, adding to sector standards in optical fibre production.

The Duty of Diameter Measurement in High Quality Control

Although diameter measurement may appear like a minor detail in the manufacturing of optical fibers, it plays a considerable duty in guaranteeing general quality assurance. Uniformity in diameter is essential for preserving the optical performance and architectural honesty of the fibres. Variations in diameter can cause concerns such as signal loss, increased depletion, and reduced tensile strength, eventually endangering the integrity of the fibre in various applications.

Quality control processes integrate specific diameter dimension to identify issues early in manufacturing. By implementing an optical fibre diameter analyser, makers can determine any type of inconsistencies from defined resistances, facilitating instant corrective actions. This positive strategy not only improves product high quality however likewise lessens waste and minimizes production costs.

Conformity With Sector Criteria and Rules

Compliance with market standards and laws is crucial for the accurate operation of an optical fibre diameter analyser. Abiding by these guidelines assurances that manufacturers preserve top quality control throughout the manufacturing process. Meeting regulative demands not just enhances product dependability however additionally cultivates consumer trust fund.

Ensuring Quality Assurance

Making certain adherence to sector standards is vital for keeping the integrity and performance of optical fibre products. Quality assurance plays a crucial duty in this process, as it includes the methodical tracking of fibre diameter to ensure uniformity and integrity. An optical fibre diameter analyser is a critical tool in achieving these quality standards, giving specific dimensions that assist determine variances from established specs. By using this modern technology, makers can promptly find and attend to any type of anomalies, ensuring that items fulfill the needed performance criteria. Routine analysis via such analysers not just supports product top quality however also boosts client count on and complete satisfaction. Ultimately, durable quality assurance measures cultivate a competitive side in the optical fibre market, advertising long-lasting success and this page conformity with requirements.

Meeting Governing Demands

As suppliers navigate the complexities of the optical fibre sector, conference regulatory demands comes to be vital for assuring item safety and performance. Compliance with industry requirements not only minimizes potential dangers yet also improves customer self-confidence in the items supplied. An optical fibre diameter analyser plays a vital function in this procedure, permitting manufacturers to verify that their products abide by specified dimensions and tolerances. By utilizing such analyzers, companies can ensure that their optical fibers fulfill the stringent guidelines stated by market authorities. This aggressive approach to quality control not just facilitates compliance however additionally streamlines the production procedure, decreasing the chance of expensive recalls or denials. Inevitably, adherence to governing criteria is critical for keeping a competitive side out there.

Benefits of Accurate Diameter Dimension

Exact diameter measurement plays a vital role in the performance and dependability of optical fibres. Ensuring that fibers fulfill defined diameter resistances lessens signal loss and maximizes transmission performance, directly affecting total system efficiency. This precision is vital in preserving optimal light propagation, as also small discrepancies can lead to raised attenuation and diminished optical signal top quality.

Exact measurements boost compatibility between parts in fibre optic systems, promoting smooth assimilation and minimizing the risk of failings. Consistent diameter dimensions also add to improved manufacturing processes by determining potential flaws early, consequently lessening waste and decreasing production expenses.

Integrating Optical Fibre Diameter Analysers Into Manufacturing

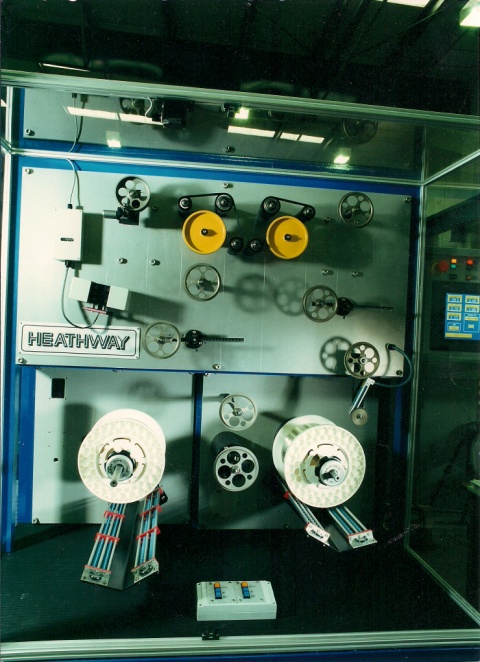

Integrating optical fibre diameter analysers right into manufacturing procedures improves the ability to keep rigorous top quality control procedures. By utilizing these analysers, manufacturers can attain specific and constant measurements of fibre diameters, which is essential for ensuring product performance and reliability. The combination process typically entails placing analysers at key factors along the production line, enabling real-time surveillance and prompt responses on diameter variants.

This positive technique permits quick adjustments to the manufacturing specifications, decreasing the risk of defects and waste. Additionally, the information gathered can be used for statistical procedure control, adding to constant improvement efforts. Operators are encouraged with actionable insights that facilitate educated decision-making pertaining to material usage and manufacturing methods. Ultimately, the incorporation of optical fibre diameter analysers not just improves item high quality however likewise supports conformity with industry criteria, reinforcing a firm's credibility for excellence in the affordable optical fibre market.

Future Patterns in Optical Fibre Measurement Innovation

Arising developments in optical fibre dimension technology are poised to reinvent the sector. The incorporation of man-made knowledge and device understanding is anticipated to improve precision and performance in diameter evaluation. These technologies enable real-time data handling, permitting prompt changes during manufacturing, thus reducing waste. Additionally, the growth of non-contact dimension strategies assures a decrease in physical communication with fibers, preserving their honesty.

In addition, miniaturization of measurement gadgets is anticipated to lead to more portable and straightforward remedies, helping with on-site analyses. fibre testing equipment. Combination with IoT platforms will certainly make it possible for remote tracking and data collection, promoting improved predictive upkeep and high quality control

As markets progressively demand greater efficiency requirements, the advancement of optical fibre measurement tools will play an essential duty in satisfying these expectations, ensuring that manufacturers can regularly deliver premium products while adhering to strict regulatory criteria.

Frequently Asked Inquiries

How Frequently Should Optical Fibre Diameter Measurements Be Performed?

Frequency of optical fibre Get More Info diameter dimensions normally depends upon manufacturing volume and top quality demands. Regular checks, usually everyday or weekly, assist guarantee constant quality and adherence to requirements, reducing possible visit site problems in fibre production processes.

What Are the Normal Costs of Optical Fibre Diameter Analysers?

The normal costs of optical fibre diameter analysers vary extensively, ranging from a number of thousand to tens of countless bucks, depending on functions, accuracy, and producer, influencing decisions for services purchasing top quality dimension modern technology.

Can Diameter Analysers Be Adjusted On-Site?

Diameter analysers can frequently be adjusted on-site, enabling instant changes to guarantee precision. However, the particular procedures and demands may vary relying on the maker's standards and the innovation made use of in the analyser.

What Types of Fibres Can Be Calculated With These Analysers?

Optical fibre diameter analysers can determine numerous fibre types, consisting of single-mode, multi-mode, specialty, and large-core fibres. Each type calls for particular calibration setups to guarantee precise and reliable diameter measurements throughout the production process.

Are There Specific Maintenance Requirements for Diameter Analysers?

Diameter analysers require regular calibration to assure accuracy, along with regular cleansing to prevent debris build-up. Additionally, checking software application updates and evaluating mechanical parts contribute to their optimal performance and longevity in measuring fibre diameters effectively.